August 30th, 2018

- Sustainability

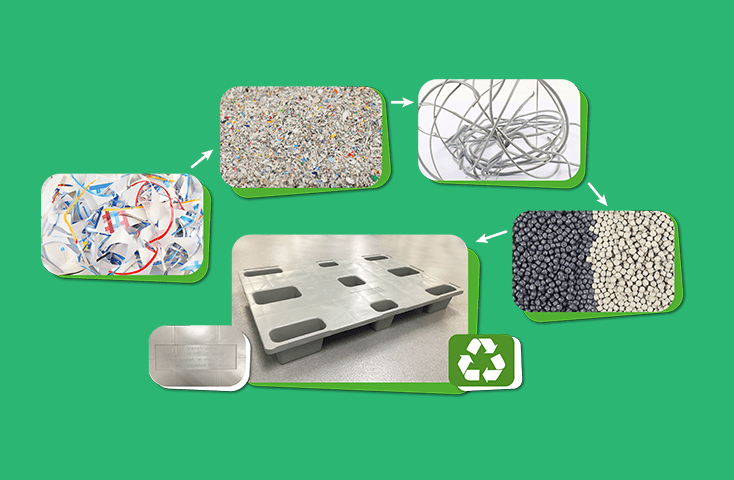

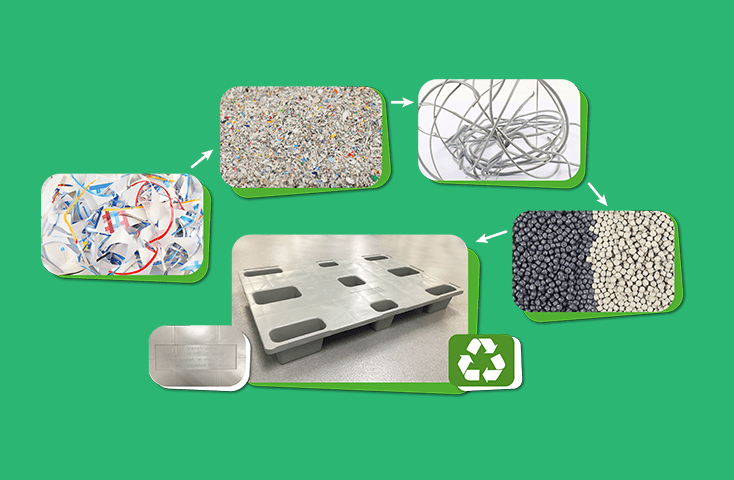

From plastic waste to plastic pallet

Sustainability is central to us. For our production process, we therefore attach great importance to efficient waste management and circular solutions. That is why we make plastic pallets from our own polypropylene IML waste. This way, nothing goes to waste.

We produce in mold labels. Inevitably, that production generates waste, mainly plastic waste (polypropylene). 3,500 tons of that waste is processed annually by Plastic Recycling Verstraete (PRV), the spin-off company from MCC Verstraete, into a new basic raw material: recycled PP granulate (rPP).

Circular economy

"Until recently, those granules were sold to third parties to make new products," explains purchasing director Rudi Verhulst. "Until we found out that we could process them ourselves into usable materials, namely pallets."

In other words, we decided to start processing some of our own waste into materials that we can use in our own production process. For us, it's a great way to contribute to the circular economy.

Rudi Verhulst, Purchasing Manager at MCC Verstraete

Strong like wood

Each year, MCC Verstraete produces 12,000 to 14,000 pallets in the same format as the standard euro pallets and just as strong, if not stronger than the wooden ones. And not only that, the pallets are "personalized" in the sense that it is clearly visible that they are MCC Verstraete pallets, produced from our own waste material. This is how we share our sustainability efforts with the world.

But that is not our only contribution to the circular economy. Since our customers are injection molding companies that work with polypropylene, they in turn can use the recycled polypropylene pallets for their business processes, either for internal use (transportation) or to be recycled again into granulates, giving them a third life. "The regranulates can be processed for the production of flower pots or even garden furniture, for example," concludes purchasing manager Rudi Verhulst.